1. Basic Concepts: Simple Form and Combined Form

Diamond is a well-known superhard material. Artificial diamond crystal come in various types, broadly categorized into simple forms and combined forms, each with distinct characteristics and applications.

Simple forms: Crystal composed of the same type of crystal faces (e.g., (100) or (111) planes), featuring regular structures such as octahedrons and cubic crystals.

Combined forms: Aggregates of two or more types of crystal faces (e.g., (100) or (111) planes), such as hexoctahedrons, with complex structures and wide-ranging applications.

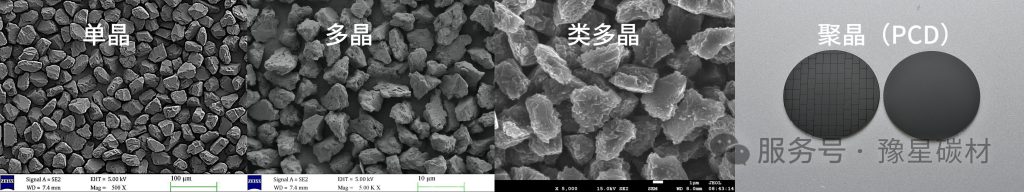

2. Comparison of Four Diamond Types

| Category | Core Definition | Manufacturing Method | Physical Properties | Core Applications |

| Single Crystalline Diamond | A single crystal face structure with uniform arrangement in three-dimensional space, no grain boundaries, and few defects. | Synthesis of graphite and a catalyst in a cubic press under high temperature and pressure. | Extremely high hardness, thermal conductivity up to 2200 W/(m·K), and excellent optical transmittance. | Ultra-precision machining (mirror grinding), semiconductor heat dissipation, aerospace optical devices, high-power laser materials. |

| Polycrystalline Diamond | Nanoscale small particles are disorderly arranged and bonded through unsaturated bonds, exhibiting high toughness. | Graphite is instantaneously generated via an explosion method (high-temperature and high-pressure shock waves). | Slightly lower hardness but high wear resistance, thermal conductivity close to 2000 W/(m·K), and outstanding self-sharpening property. | Grinding of silicon carbide/sapphire, coating for metal molds, impact-resistant cutting tools, heat sinks. |

| Polycrystalline-like Diamond | Honeycomb structures formed by etching single-crystal surfaces combine the hardness of single crystals with the self-sharpening property of polycrystals. | Single-crystal diamond is processed through special techniques (e.g., surface modification). | Moderate hardness, high grinding efficiency, and good roughness control. | Precision grinding and polishing (ceramics, optical lenses), machining of multi-material composite workpieces, economical alternatives to polycrystals. |

| Polycrystalline Aggregate (PCD) | Aggregates sintered from single crystals and binders under high temperature and pressure show isotropic properties. | Sintering of single crystals with metal or ceramic binders under high temperature and pressure. | Extremely high wear resistance, low friction coefficient, excellent thermal conductivity, and strong thermal stability. | Super-hard tools for geological drilling bits, precision cutting, electronic heat dissipation components, wear-resistant coatings. |

3. Key Differences and Selection Guide

(1) Production Processes

(2) Structure and Properties

(3) Applications Scenarios

4. Why Choose Yuxing Carbon Material Co., Ltd?

The diverse morphologies of diamond crystals endow them with broad application potential in industries such as manufacturing, optics, and semiconductors. Selecting the appropriate type can significantly enhance processing efficiency and material performance!

Henan Yuxing Carbon Material Co., Ltd. has deep expertise in the superhard materials field, mastering multiple core technologies. We provide customized production based on customer needs and offer cost-effective solutions. With technology leadership and excellent quality as our principles, we strive to boost your industrial upgrading!

Contact:

Siya

TEL: +86 18238698305

Whatsapp: +86 18238698305

E-mail: siya@mcrondiamond.com

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on