① Cutting processing

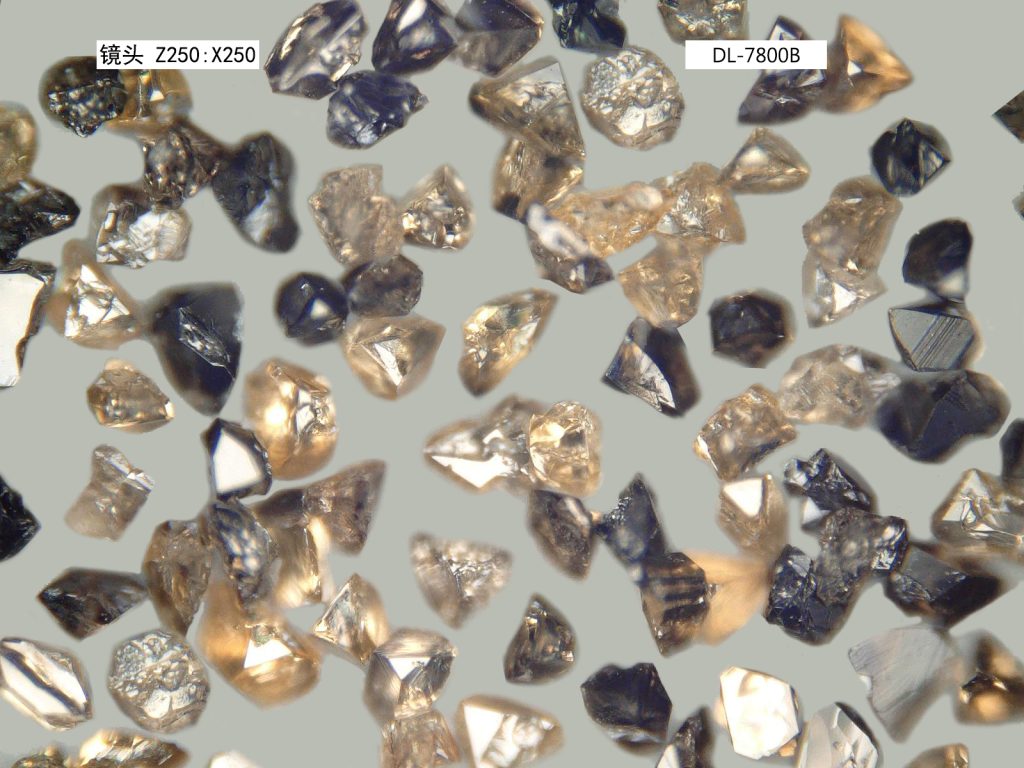

CBN cutting tools perform excellently in machining difficult-to-machine high-hardness steel materials such as hardened steel, high-speed steel and die steel. For example, in the manufacturing of automobile engines, when precisely cutting components like quenched crankshafts and camshafts, CBN cutting tools can effectively remove materials and ensure the quality and precision of the machined surfaces. This is because they can withstand high temperatures and high cutting forces during high-speed cutting while maintaining good wear resistance.

For cast iron materials, such as nodular cast iron and gray cast iron, CBN cutting tools can also play to their strengths. In the machining of cast iron products like machine tool beds and mechanical parts, the cutting edges of CBN cutting tools can remain sharp for a long time, reducing the frequency of tool changes and improving machining efficiency.

② Grinding processing

CBN grinding wheels are important tools to for precision grinding. In the bearing manufacturing industry, they are used to grind in the high-precision surfaces of inner and outer rings of bearings. Due to the high hardness and good thermal stability of CBN, during the grinding process, it can ensure the requirements for form and position tolerances such as roundness and cylindricity of the bearing surfaces, and can effectively prevent the workpiece surfaces from being burned.

In the terms of tool grinding, CBN grinding wheels can be used to grind cemented carbide tools and high-speed steel tools, enabling the cutting edges of the tools to obtain good quality and improving the cutting performance of the tools.

① Semiconductor material processing

CBN can be used for the lapping and polishing of semiconductor silicon wafers. In the process of chip manufacturing, extremely high requirements are imposed on the flatness and smoothness of the surface of silicon wafers. The lapping discs and polishing pads made of CBN materials can precisely remove the flaws on the surface of silicon wafers, thus meeting the technological requirements of chip manufacturing.

It is used for machining high-temperature alloy components of aero-engines. These components are made of materials with high hardness and good toughness, and they need to withstand high temperatures and high stresses in the working environment. CBN cutting tools can adapt to such complex machining conditions, conduct effective machining on components like turbine blades and disk shafts, ensure the precision and quality of the parts, and thus guarantee the high performance and reliability of aero-engines.

When manufacturing high-precision mechanical parts, such as precision gears and lead screws, CBN tools can achieve fine machining and ensure the quality indicators such as the dimensional accuracy and surface roughness of the parts. For example, in the processing of high-precision gears, CBN cutting tools can precisely cu the tooth profiles, making gear transmission smoother and more efficient.

Contact

Siya

TEL : +86 18238698305

Whatsapp : +86 18238698305

Facebook : Siya Miao

E-mail: siya@microndiamond.com

I am here for you.

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on