Diamond and Cubic Boron Nitride (CBN) are both superhard materials, and here’s how they compare:

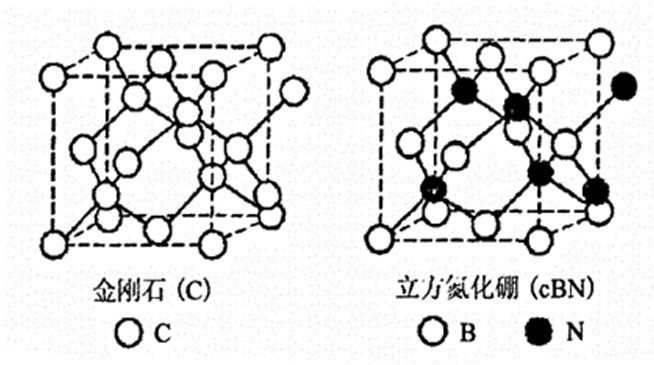

① Diamond:

It is a simple substance composed of carbon elements. The carbon atoms in it are arranged in a regular tetrahedral structure through covalent bonds. This compact structure endows diamond with extremely high hardness.

② CBN:

It main component is cubic boron nitride, which is a compound formed by the combination of boron atoms and nitrogen atoms through covalent bonds. Its crystal structure is similar to that of diamond, and it is also a material with a high hardness.

① Diamond:

It’s the hardest substance known in nature, with a Mohs hardness of 10. This enables it to perform excellently in grinding and cutting high-hardness materials. For example, it can be used to cut glass, stone and so on.

② CBN:

Its hardness is slightly inferior to that of diamond, and its Mohs hardness is approximately 9.5-9.75. However, the hardness of CBN is already high in many industrial application scenarios.

① Diamond:

It is prone to chemical reactions with iron group elements at high temperatures. In the air, when the temperature reaches around 700-800℃, diamond will start to oxidize, and its structure will be gradually damaged, resulting in a decrease in hardness. Therefore, the service life of diamond tools will be affected when processing ferrous metals such as steel.

② CBN:

It has good thermal stability and can withstand high temperature of 1200-1300℃ in the air without significant oxidation reactions. This makes CBN highly suitable for processing high-hardness ferrous metals, such as quenched steel, high-speed steel and so on.

① Diamond:

It has relatively stable chemical properties, but it will react under the specific chemical environments. Besides reacting with iron group elements at a high temperatures as mentioned above, it will also react with strong oxidants.

② CBN:

It has good chemical stability and shows relatively good tolerance to most metals, acids, alkalis and other chemical substance. This enables CBN tools maintain good performance in various complex processing environments.

① Diamond:

-Stone processing:

It is used for cutting stones such as marble and granite. Its high hardness enables it to cut hard stones quickly and effectively, and the cut surfaces are relatively smooth.

-Optical glass processing:

It is widely applied in grinding and polishing glass products like optical lenses, which can make the lenses achieve high precision and smoothness.

-Drilling industry:

As a material for drill bits, it is used for drilling work in fields such as petroleum and geological exploration, and it can drill holes in hard rock formatiions.

② CBN:

-Metal processing:

It is mainly used for processing ferrous metals and their alloys. For example, it is used for grinding auto engine parts(such as crankshafts, camshafts, etc). These parts are usually made of high-hardness materials like quenched steel. CBN cutting tools can provide high-precision and high-efficiency processing.

-Processing of superhard materials:

It can be used for processing materials with high hardness such as ceramics, and it plays an important role in the fields of precision machining and aerospace component processing.

Contact:

Siya

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on