The applications of diamond powder in the photovoltaic field are mainly in the following aspects:

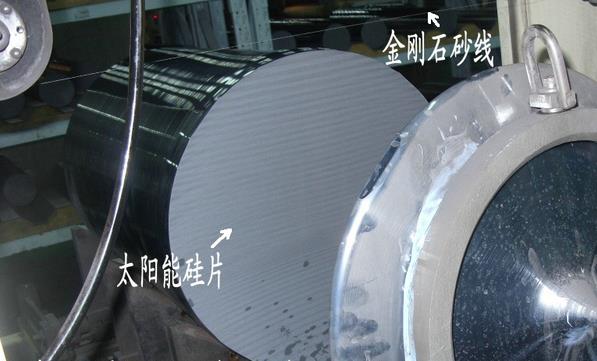

Ⅰ Diamond Wire Cutting

1. Wafer Cutting:

Diamond wire cutting is currently one of the main methods for cutting crystalline silicon wafers in the photovoltaic industry. By electroplating diamond particles on the surface of metal wires and taking advantage of the high hardness and wear resistance of diamonds, and adopting high-speed two-sided grinding cutting in both forward and reverse directions, silicon rods can be cut into wafers as thin as paper.This cutting method has the advantages of fast cutting speed, high wafer yield, low cutting loss and little environmental pollution. It can significantly reduce the production costs of wafer manufacturing enterprises and improve the yield on investment of photovoltaic installations.

2. Cutting of the Materials:

Besides wafer cutting, diamond wire can also be used for cutting other hard and brittle materials in the photovoltaic field, such as sapphire, magnetic materials and so on. These materials also have important applications in the photovoltaic industry chain. For example, sapphire can be used to make LED substrates. Diamond wire cutting can meet the high-precision cutting requirements of these materials.

Ⅱ Diamond Powder

1. Wafer lapping and polishing:

Diamond powder has extremely high hardness and grinding performance and can be used in the wafer lapping and polishing processes. During the wafer production process, the surface of wafers after cutting is relatively rough. It is necessary to improve the flatness and smoothness of wafers through processes such as lapping and polishing, so as to reduce the surface roughness of wafers, decrease the reflection and scattering of light, and enhance the photovoltaic conversion efficiency of wafers.

2. Cutting fluid additive:

Diamond powder can also be added to the cutting fluid as an important additive. During the cutting process, the diamond powder in the cutting fluid can pay the role of suspension, lubrication and cooling, reduced friction and hear generation during cutting, improve cutting efficiency and quality, and at the same time extend the service life of cutting tools.

Contact

Yuxing: Siya

Phone: +86 182 3869 8305

Whatsapp: +86 182 3869 8305

E-mail: siya@microndiamond.com

Facebook: Siya Miao

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on