① Diamond powder has an extremely high hardness with a Mohs hardness of 10, make it the hardest substance in nature. During the process of oil drilling, drill bits need to withstand tremendous friction and pressure. By embedding diamond powder in the cutting edge parts of drill bits, the wear resistance of the drill bits can be significantly improved. For example, in the drilling of deep oil wells, drill bits have to penetrate through various rock layers with different hardnesses, such as granite, sandstone and so on. Ordinary drill bits are prone to wear, while drill bits containing diamond powder can maintain sharp cutting edges for a long time, reduce the frequency of drill bit replacement and improve the drilling efficiency.

② The wear resistance of diamond powder can also reduce the drilling cost. Frequent replacement of drill bits will not only increase the purchase cost of drill bits but also delay the drilling time due to the replacement process and increase labor costs and so on. Using drill bits containing diamond powder can avoid these problems to some extent.

① Diamond powder can enhance the cutting efficiency of drill bits. It can break rocks more effectively when the drill bits rotate and drill into rocks. Its sharp particle shape and high hardness enable it to break rocks into smaller particles like countless tiny cutting tools when it comes into contact with rocks. This crushing method is more precise than that of ordinary drill bits, producing smaller cuttings, which is beneficial for the discharge of cuttings.

② For some special rock structures, such as dense shale or formations containing hard nodules, the cutting performance advantages of diamond powder are even more obvious. It can precisely cut into the weak parts of the rocks, making it easier for the drill bits to drill in and reducing the phenomenon of drill bit sticking. During the drilling process of shale gas exploitation, shale formations are usually rather dense, and drill bits with diamond powder can break shale better to ensure the smooth progress of the drilling work.

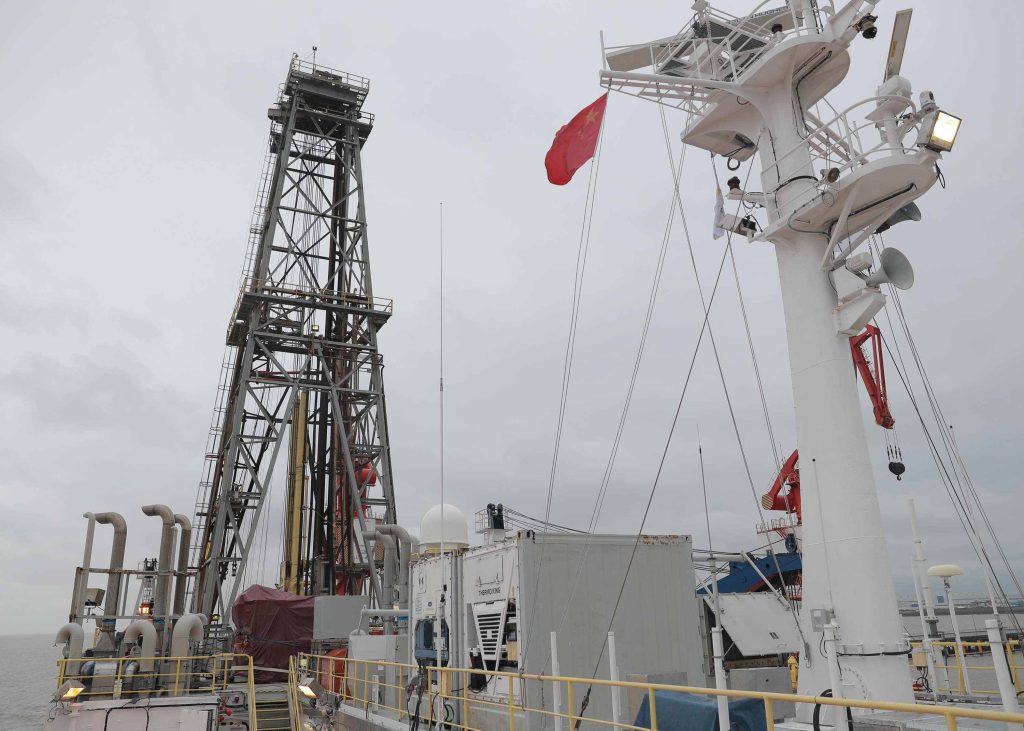

① In oil drilling, the stability of drill bits is of great importance. The distribution of diamond powder on the surface of drill bits can optimize the mass distribution of the drill bits, making them more balanced during the high-speed rotation process. For example, on offshore oil drilling platform, factors such as sea waves can cause certain shaking of the drilling equipment, and thus the stability of the drill bits becomes even more crucial. Drill bits containing diamond powder can better resist these external interferences, maintain a stable drilling state and improve the drilling precision.

② Moreover, the combination of diamond powder and the base material of the drill bit can increase the overall strength of the drill bit. This enables the drill bit to be less likely to deform or get damaged when it is subjected to high torque and high axial force, ensuring the safety and continuity of the drilling process.

Contact

Yuxing: Siya

Phone: +86 182 3869 8305

Whatsapp: +86 182 3869 8305

E-mail: siya@microndiamond.com

Facebook: Siya Miao

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on