Diamond powder has important applications in cutting tools, which are mainly reflected in the following types of cutting tools:

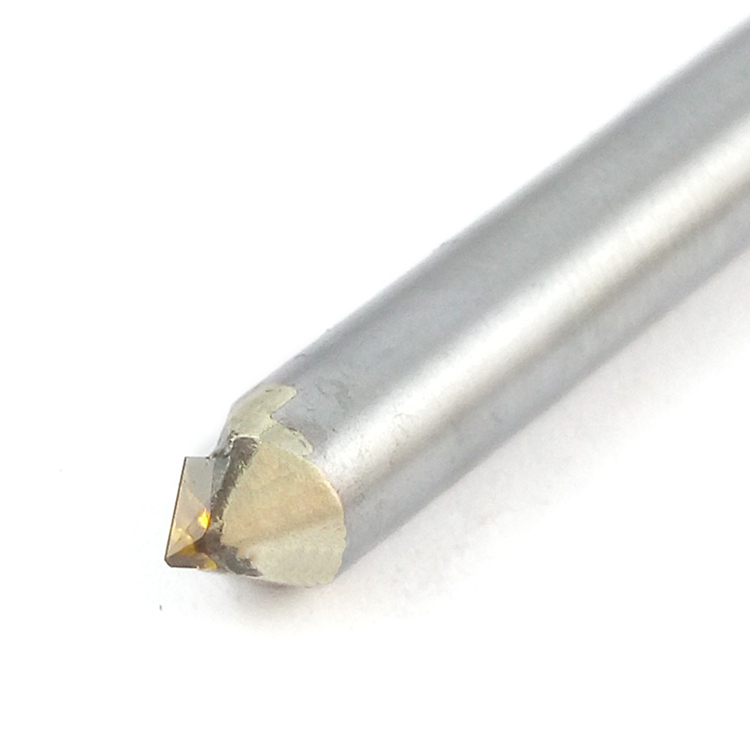

①. Manufacturing of cutting tool inserts:

PCD cutting tools are superhard composite materials formed by mixing diamond powder with a small amount of metal powder(such as cobalt, etc.) and then sintering and processing them under high temperature and high pressure. When made into inserts, they can be used for turning various non-ferrous metals, such as aluminum, copper, magnesium and their alloys. They can also be used to process cemented carbides and non-metallic materials with extremely high wear resistance, such as fiber-reinforced plastics, metal matrix composites, and wood. Compared with cemented carbide inserts, PCD inserts have higher hardness, better wear resistance and sharpness. They can adopt higher feed rates and cutting speeds, improving processing efficiency and resulting in a higher surface finish of the machined workpieces.

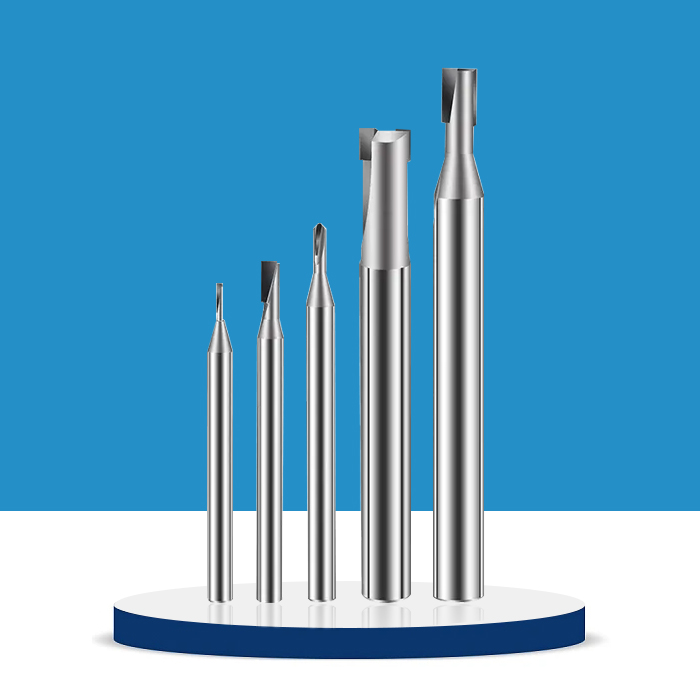

② Manufacturing of non-standard inserts:

For some working conditions with complex structures, strict tolerance requirements and complicated processing procedures, the use of mechanically clamped PCD non-standard inserts can greatly improve processing efficiency and simultaneouly reduce production costs.

① Improving the performance of cutting tools:

A diamond thin film with a thickness ranging from 1 to 25 μm is directly deposited on substrates such as cemented carbide or ceramic by means of Chemical Vapor Deposition (CVD), thus forming diamond-coated cutting tools. This kind of cutting tools combines the toughness of the substrate materials with the advantages of the diamond coating, such as high hardness and excellent wear resistance. It has outstanding cutting performance and can be applied to various cutting tools with complex geometries. It is an ideal cutting tool for processing difficult-to-machine materials and is suitable for high-speed machining, such as aerospace materials like aluminum-titanium alloys and difficult-to-machine non-metallic materials like graphite electrodes.

① Precision grinding processing:

Diamond powder has high hardness and good wear resistance, and can be used as a grinding material for the grinding parts of cutting tools. When performing finishing and regrinding on cutting tools, diamond powder can effectively remove tiny flaws and burrs on the surface of the tools, improve the quality of the cutting edge and the surface finish of the tools, thus ensuring the cutting performance and service life of the tools.

② Processing of special materials:

It is used in cutting tools for processing some special materials, such as cutting tools for processing hard and brittle materials like ceramics, optical glass, and cemented carbides. The high hardness and good grinding performance of diamond powder enable efficient and precise processing of these materials.

Contact

Yuxing: Siya

Phone: +86 182 3869 8305

Whatsapp: +86 182 3869 8305

E-mail: siya@microndiamond.com

Facebook: Siya Miao

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on