The application of diamond in the cutting field is very extensive.

The details are as follows:

3. Cutting of gems and jades:

① Diamond cutting:

Diamond is the hardest substance in nature. Therefore, diamond tools are indispensable in the cutting and processing of diamonds. Rough diamond stones need to undergo precise cutting and grinding to show their brilliant luster and value. Diamond cutting tools can perform various cutting and grinding operations according to the shape, size and quality of diamonds, such as cutting out different diamond facets and shapes, so as to make the optical properties of diamonds be brought into full play.

② Jade cutting:

The hardness of jades such as jadeite and Hetian jade is also relatively high, and traditional cutting tools can hardly meet the cutting requirements. Diamond cutting tools can be used for cutting, carving and other processing of jades, which can not only improve the processing efficiency but also ensure the quality and aesthetics of jade products. For example, some large jade ornaments and pendants all need to be cut and carved with diamond tools.

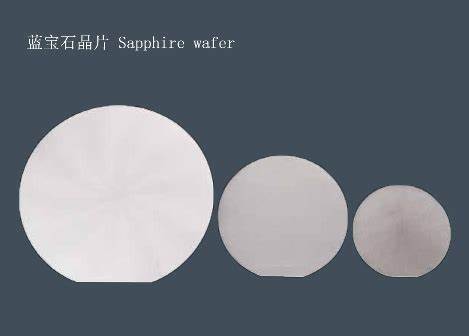

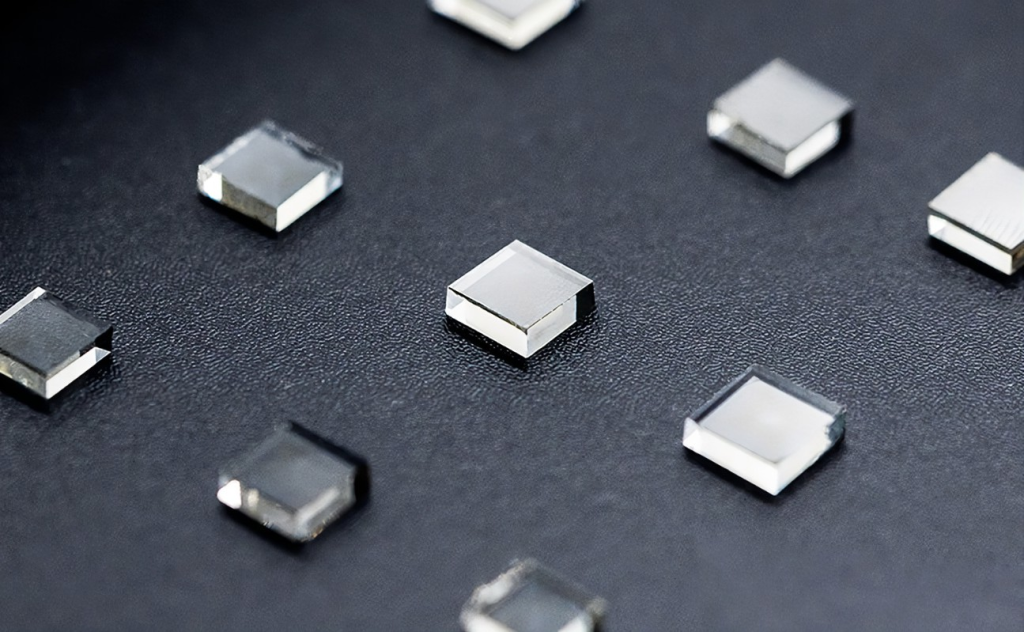

4. Cutting of semiconductor and electronic materials:

① Silicon wafer cutting:

In the semiconductor industry, silicon wafers are the basic materials for manufacturing integrated circuits. The diamond wire saw technology is widely used in the cutting of silicon wafers. It has the advantages of fast cutting speed, narrow kerf and small material loss. Diamond wire saws can cut silicon ingots into silicon wafers as thin as paper, providing high-quality silicon wafer materials for the subsequent semiconductor manufacturing processes.

② Electronic glass cutting:

Electronic glass is a key basic material in the electronic information industry. For example, liquid crystal displays and touch screens all need to use electronic glass. Diamond cutting tools can perform high-precision cutting on electronic glass, ensuring the dimensional accuracy and edge quality of the glass and meeting the strict requirements of electronic devices for glass substrates.

5. Cutting of metal materials (specific metals and alloys):

① Cutting of difficult-to-machine metal materials:

For some metal materials with high hardness and good wear resistance, such as tungsten alloys and titanium alloys, ordinary cutting tools suffer from severe wear and low cutting efficiency. Due to its high hardness and good wear resistance, diamond cutting tools can effectively cut these difficult-to-machine metal materials. For example, in the aerospace field, the manufacturing of some key components requires the use of diamond cutting tools to cut and process special metal materials.

② Cutting of precision metal parts:

In the processing of some precision metal parts with extremely high requirements for cutting precision, diamond cutting tools are also applied. Diamond cutting tools can achieve the cutting of metal parts with tiny sizes, and the quality of the cut surface is high, which can meet the high-precision processing requirements of metal parts in fields such as precision instruments and medical devices.

Contact

Yuxing: Siya

Phone: +86 182 3869 8305

Whatsapp: +86 182 3869 8305

E-mail: siya@microndiamond.com

Facebook: Siya Miao

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on