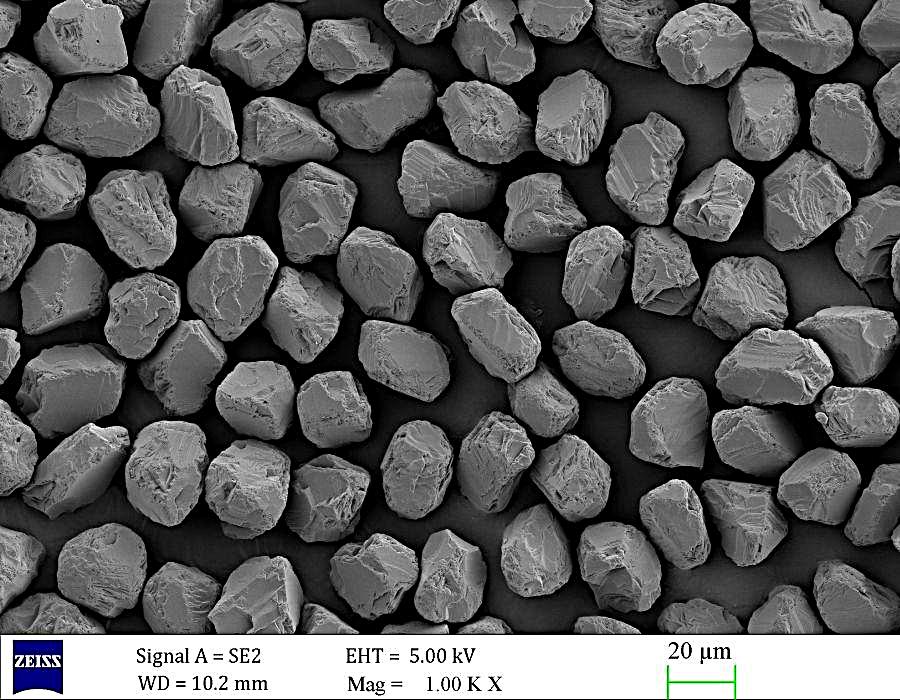

After the micron diamond completes the processes of ball milling and crushing, shaping processing and rough purification, there is a very important process, which is to perform particle size classification on the product.

The main purpose is to make the particle size distribution as concentrated as possible and completely eliminate oversized particles. Since the micron diamond particles are too fine, traditional screen classification cannot achieve accurate classification. Choosing a scientific, efficient and precise classification method is especially important.

Under the same specific gravity, diamond particles of different particle sizes have different sedimentation rates in water.

The natural sedimentation method is based on this principle. The particle size is classified by controlling the sedimentation height and sedimentation time. Particles are subjected to three forces in the liquid, namely the gravity generated by the inherent mass of the particle, the buoyancy of the liquid, and the resistance of the medium to the particle. The sedimentation velocity of particles is related to factors such as the contact area between the particles and the medium, the viscosity of the liquid, and the frictional resistance encountered by the particles when moving in the medium.

The principle of centrifugal classification is the same as that of natural sedimentation classification. The difference is that the centrifugal method uses the centrifugal force generated by a centrifuge instead of gravity to classify micron diamond products.

For coarser particles, due to the heavy weight of the particles and short sedimentation time, the natural sedimentation method can elongate the sedimentation distance of particles with similar particle sizes, which is beneficial for the fine classification of micron diamond products of similar specifications. But for finer particles, due to the very small self-weight of the particles, the speed of free sedimentation in the gravitational field is very slow.

Using the natural sedimentation method again will greatly extend the production cycle and occupy a large amount of classification containers and sites. Ultra-fine particles cannot even be effectively classified due to Brownian motion and the interference sedimentation effect between particles. In the centrifugal force field, the centripetal acceleration far exceeds the gravitational acceleration, greatly increasing the speed of movement of the micron powder particles and thus speeding up the classification speed. Therefore, most diamond powder production enterprises use a combination of natural sedimentation method and centrifugal method to produce full-specification micron powder from fine to coarse.

Sales:

──Siya

TEL: +86 18238698305

Whatsapp: +86 18238698305

E-mail: siya@microndiamond.com

Contact us

We are here for you

Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.Henan Yuxing Carbon Material Co.Ltd. is professional manufacturer and supplier of micron and nano industrial diamond powder in the world.

follow us on